- info@matltech.com

- E2-1-1011 Global Center, No.1700 Tianfu Avenue North, Chengdu 610041, China.

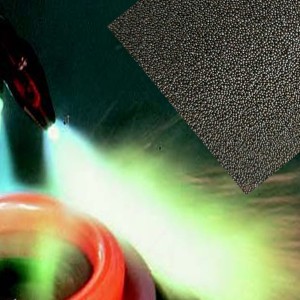

Cemented Carbide Hardsurfacing Powder

Katrangan

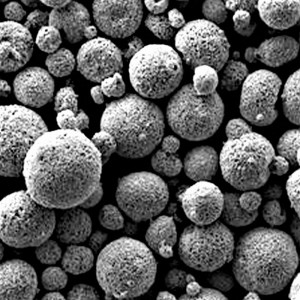

Cemented Carbide Hard-surface Powder, kalebu Tungsten Carbide adhedhasar utawa Chromium Carbide adhedhasar Thermal Spraying Powder (TSP), minangka bubuk abu-abu peteng sing bunder utawa meh bunder kanthi flowability apik, diproses kanthi agglomerated lan sintered (A + S) utawa sintered lan crushed (S + C), fitur ing sifat unik kayata resistance abrasion apik, resistance karat lan resistance suhu dhuwur, suhu operasi maksimum kanggo tungsten carbide adhedhasar kira-kira 500 ° C, krom karbida adhedhasar siji kira-kira 700 ° C-870 ° C.Cemented Carbide Hard-surfacing Powder utawa Tungsten Carbide Hard-surfacing Powder utawa Thermal Spraying Powder cocok kanggo macem-macem jinis uyuh lan plasma uyuh welding etc ing pertambangan, Petroleum, industri metalurgi, mesin tetanèn, baja lan industri construction.

Pangiriman

Cemented Carbide Hard-surfacing Powder ing Western Minmetals (SC) Corporation bisa dikirim kanthi basis Tungsten Carbide kayata WC-12Co, WC-17Co, WC-10Co4Cr, WC-10Ni, WC-12Ni, WC-17Ni, WC-15NiCr etc lan Chromium Carbide adhedhasar kayata Cr3C2-20NiCr, Cr3C2-25NiCr etc ing ukuran 10-30um, 10-45um, 20-59um bubuk etc, paket 25kg ing kantong plastik karo drum wesi njaba.

Rincian

Tag

Spesifikasi Teknis

Cemented Carbide Hard-surface Powderutawa Thermal Spraying Powder ing Western Minmetals (SC) Corporation bisa dikirim karo Tungsten Carbide adhedhasar kayata WC-12Co, WC-17Co, WC-10Co4Cr, WC-10Ni, WC-12Ni, WC-17Ni, WC-15NiCr etc lan Chromium Karbida adhedhasar kayata Cr3C2-20NiCr, Cr3C2-25NiCr etc ing ukuran 10-30um, 10-45um, 20-59um bubuk etc, paket 25kg ing kantong plastik karo drum wesi njaba.

Thermal Spray Powder Cemented Carbide Hard-lumahing Powder

| Ora. | Item | Spesifikasi standar | ||||||

| 1 | sasmita | TC% | Co% | Cr% | Ni % | Fe% | O% | |

| 2 | TSP42 | WC-12 Kab | 5.2-5.6 | 11.5-12.5 | - | - | ≤1.0 | ≤0.5 |

| TSP42D | WC-12 Kab | 5.2-5.6 | 11.5-12.5 | - | - | ≤0.15 | ≤0.5 | |

| TSP43 | WC-17 Kab | 4.7-5.2 | 16.5-17.5 | - | - | ≤1.0 | ≤0.5 | |

| TSP43D | WC-17 Kab | 4.7-5.2 | 16.5-17.5 | - | - | ≤0.15 | ≤0.5 | |

| TSP45 | WC-10Co4Cr | 5.2-5.6 | 9.1-10.1 | 3.0-4.5 | - | ≤1.0 | ≤0.5 | |

| TSP45D | WC-10Co4Cr | 5.2-5.6 | 9.1-10.1 | 3.0-4.5 | - | ≤0.15 | ≤0.5 | |

| TSP46D | WC-9Co5Cr1Ni | 5.1-5.8 | 8.5-9.5 | 4.5-5.5 | 0.8-1.2 | ≤0.3 | ≤0.5 | |

| TSP47D | WC-10Ni | 5.3-5.8 | - | - | 9.0-11.0 | ≤0.2 | ≤0.5 | |

| TSP48D | WC-20Cr3C2-7Ni | 5.8-6.4 | - | 20-23 | 6.0-8.0 | ≤0.5 | ≤0.5 | |

| TSP49D | Cr3C2-37WC-18NiCoCr | 7.8-8.4 | 3.0-4.0 | 39.5-42.5 | 10.5-12.5 | ≤0.5 | ≤0.5 | |

| TSP51D | Cr3C2-20 NiCr | 9.7-10.7 | - | imbangan | 15.0-17.0 | ≤0.15 | ≤0.5 | |

| TSP52D | Cr3C2-25NiCr | 9.1-10.1 | - | imbangan | 19.0-21.0 | ≤0.15 | ≤0.5 | |

| TSP91D | WC-12Ni | 5.2-5.6 | - | - | 11.5-12.5 | ≤0.2 | ≤0.5 | |

| TSP92D | WC-17Ni | 5.0-5.3 | - | - | 16.5-17.5 | ≤0.2 | ≤0.5 | |

| TSP93D | WC-15NiCr | 5.0-5.4 | - | 2.5-3.5 | 11.5-12.5 | ≤0.5 | ≤0.5 | |

| 3 | Kapadhetan | WC adhedhasar | Kapadhetan sing katon ≥4,0 g / cm3 | |||||

| Cr3C2adhedhasar | Kapadhetan Nyoto TSP49D ≥2.5g/cm3, TSP51D TSP52D ≥2,0 g/cm3 | |||||||

| 4 | Ukuran | μm | 53-20 | 45-20 | 45-15 | 45-11 | 38-10 | 30-10 |

| Tingkat aliran / 50g | WC adhedhasar | ≤18 | ≤18 | ≤18 | ≤18 | ≤18 | ≤30 | |

| Cr3C2adhedhasar | - | - | - | - | - | - | ||

| 5 | Morfologi Gandum | TSPXXD iku bunder utawa meh bunder dening Agglomerated lan Sintered | ||||||

| 6 | Packing | 25kg utawa 50kgs ing tas plastik karo drum wesi njaba | ||||||

Tips Pengadaan

- Sampel Kasedhiya Yen Panyuwunan

- Pangiriman Safety Barang Miturut Kurir / Udara / Laut

- Manajemen Mutu COA/COC

- Packing Aman & Nyaman

- Packing Standar PBB Kasedhiya Yen Panyuwunan

- Sertifikasi ISO 9001:2015

- Ketentuan CPT/CIP/FOB/CFR Miturut Incoterms 2010

- Ketentuan Pembayaran Fleksibel T/TD/PL/C Ditrima

- Layanan Sawise-Sale Dimensi Lengkap

- Inspeksi Kualitas Miturut Fasilitas Sate-of-the-art

- Persetujuan Peraturan Rohs/REACH

- Perjanjian Non-Disclosure NDA

- Kebijakan Mineral Non-Konflik

- Review Manajemen Lingkungan Reguler

- Pemenuhan Tanggung Jawab Sosial

Thermal Spray Powder

Powder lumahing hard

produk sing gegandhengan

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu