- info@matltech.com

- E2-1-1011 Global Center, No.1700 Tianfu Avenue North, Chengdu 610041, China.

Tungsten Carbide Ready-to-Press Powder

Katrangan

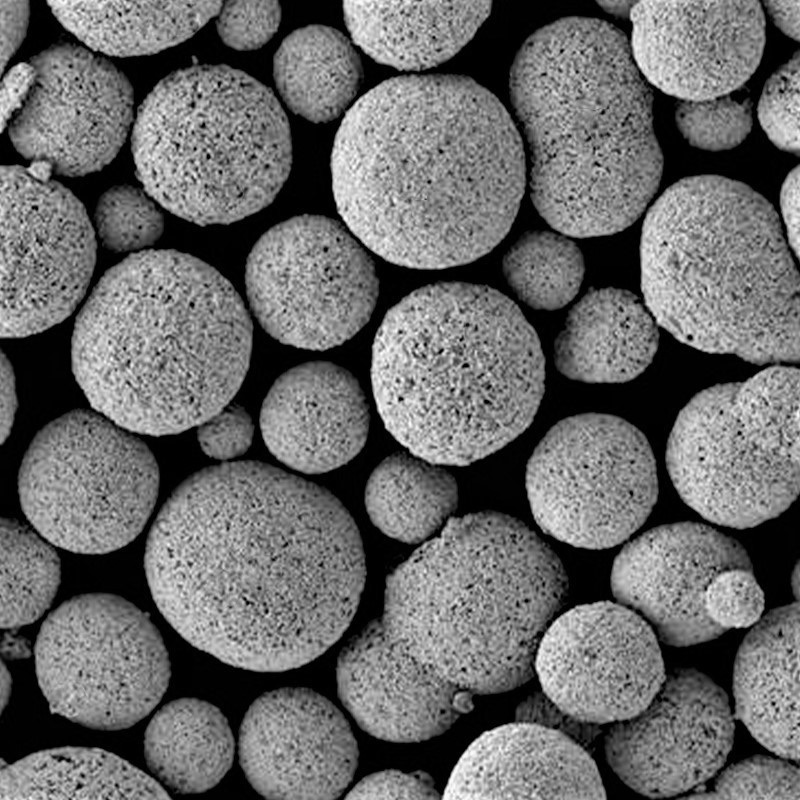

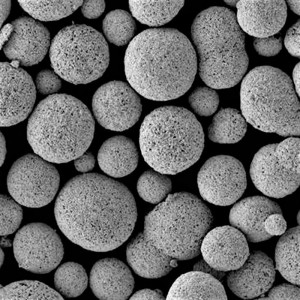

Tungsten Carbide Siap Pencet Bubuk (bubuk RTP)utawa Tungsten Carbide Grade Powder, karo katon saka partikel bundher werna abu-abu, punika free-mili bubuk minangka bahan dhasar ing produksi sintered cemented carbide produk.Kanthi nggunakake proses produksi parafin doping paling majeng lan teknologi pangatusan semprotan, Tungsten carbide siap kanggo pencet bubuk RTP wis shaped menyang granule bundher karo banget aliran-kemampuan sawise werni giling, kebak pipis lan semprotan pepe, saben granule ngemot constituent saka bahan tartamtu. , kayata tantalum karbida TaC, titanium karbida TiC, niobium karbida NbC, tantalum-niobium karbida TaNbC lan aditif liyane minangka inhibitor karo kobalt utawa nikel minangka binder kanggo entuk kinerja sing unggul.Kanthi morfologi bundher banget, flowability sampurna lan kelembapan residual minimal, bubuk RTP utawa Grade minangka bubuk kelas becik kanggo digunakake minangka bahan wiwitan kanggo ngasilake bagean Carbide Cemented kayata alat pemotong padat, alat pengeboran, alat downhole, bagean nyandhang lan presisi liyane. komponen karbida.

Pangiriman

Western Minmetals (SC) Corporation duwe pengalaman lan tim teknis sing darmabakti kanggo ngembangake lan nyedhiyakake bubuk RTP kanggo nyukupi kabutuhan khusus sampeyan, sawetara seri RTP utawa Grade Powder kanthi ukuran lan formulasi gandum sing beda kasedhiya kalebu ZK (ZK10μf, ZK30μf, ZK20, ZK30) , YG (YG6, YG8, YG10, YG10C, YG11…), lan ZP (ZP10, ZP25, ZP35) etc utawa bisa dikirim minangka bahan khusus kanggo nggayuh solusi sing sampurna.

Rincian

Tag

Spesifikasi Teknis

Tungsten Carbide Siap Pencet Bubuk

(RTP bubuk)

Western Minmetals (SC) Corporation duwe pengalaman lan tim teknis sing darmabakti kanggo ngembangake lan nyedhiyakake bubuk RTP kanggo nyukupi kabutuhan khusus sampeyan, sawetara seri RTP utawa Grade Powder kanthi ukuran lan formulasi gandum sing beda kasedhiya kalebu ZK (ZK10μf, ZK30μf, ZK20, ZK30) , YG (YG6, YG8, YG10, YG10C, YG11…), lan ZP (ZP10, ZP25, ZP35) etc utawa bisa dikirim minangka bahan khusus kanggo nggayuh solusi sing sampurna.

Tungsten Carbide Siap Pencet Bubuk (bubuk RTP)utawa Tungsten Carbide Grade Powder, kanthi morfologi bundher sing apik banget, flowability sampurna lan kelembapan residual minimal, minangka bubuk bahan sing cocog kanggo digunakake minangka bahan wiwitan kanggo ngasilake bagean Carbide Cemented kayata alat pemotong padat, alat pengeboran, alat downhole, bagean nyandhang lan komponen karbida presisi liyane.

| NO. | ITEM | SPESIFIKASI STANDARD | |||||||

| 1 | sasmita | Co% | Ukuran µm | S / 50 g | Akeh Kapadhetan | Meksa meksa KA/m | Kapadhetan g/cm3 | HRA | TRSN/mm2 |

| 2 | ZK10µF | 6 | 0.6-0.8 | 30-40 | 3.0-3.6 | 24.7-29.0 | 14.70-14.95 | 92.5 | 2000 |

| ZK30µF | 10 | 0.6-0.8 | 30-45 | 2.8-3.3 | 19.0-24.0 | 14.30-14.50 | 91.5 | 2500 | |

| ZK20 | 8 | 1.2-2.0 | 30-40 | 3.0-3.6 | 12.5-16.8 | 14.90-15.10 | 90.0 | 2200 | |

| ZK30 | 6 | 30-45 | 2.9-3.4 | 10.0-15.0 | 14.60-14.90 | 89.5 | 2300 | ||

| YG6 | 6 | 2.4-4.0 | 36 | 3.55 | 12.0-17.0 | 14.70-15.10 | 91.5 | 2200 | |

| YG6C | 6 | 10-15 | 30-40 | 3.0-3.6 | 6.4-8.3 | 14.85-15.00 | 89.5 | 2200 | |

| YG8 | 8 | 2.4-4.0 | 36 | 3.24 | 10.0-15.0 | 14.60-14.90 | 89.0 | 2400 | |

| YG10 | 10 | 2.4-4.0 | 40 | 3.24 | 9.0-12.0 | 14.40-14.70 | 88.0 | 2400 | |

| YG10C | 10 | 10-15 | 30-40 | 3.0-3.6 | 5.5-8.2 | 14.35-14.55 | 87.0 | 2450 | |

| YG11 | 11 | 2.4-4.0 | 30 | 3.50 | 8.0-13.0 | 14.20-14.60 | 87.0 | 2400 | |

| YG11C | 11 | 10-15 | 35 | 3.75 | 5.9-9.0 | 14.10-14.50 | 87.5 | 2500 | |

| YG15C | 15 | 2.4-4.0 | 31 | 2.95 | 7.0-11.0 | 13.90-14.20 | 97.5 | 2600 | |

| YG20C | 20 | 2.4-4.0 | 30-45 | 2.8-3.8 | 5.0-6.0 | 13.45-13.65 | 83.5 | 2500 | |

| ZP10-1 | 8.5 | 37 | 2.6-3.0 | 10.5-15.0 | 11.1-11.35 | 91.5 |

| ||

| ZP25 | 8.5 | 35 | 2.7-3.1 | 12.5-15.5 | 12.50-12.70 | 91.4 | 1800 | ||

| ZP35 | 10 | 30 | 3.0-3.6 | 11.5-15.5 | 12.60-12.80 | 90.5 | 2000 | ||

| 3 | Packing | 25kg utawa 50kgs ing tas plastik karo drum wesi njaba | |||||||

Tips Pengadaan

- Sampel Kasedhiya Yen Panyuwunan

- Pangiriman Safety Barang Miturut Kurir / Udara / Laut

- Manajemen Mutu COA/COC

- Packing Aman & Nyaman

- Packing Standar PBB Kasedhiya Yen Panyuwunan

- Sertifikasi ISO 9001:2015

- Ketentuan CPT/CIP/FOB/CFR Miturut Incoterms 2010

- Ketentuan Pembayaran Fleksibel T/TD/PL/C Ditrima

- Layanan Sawise-Sale Dimensi Lengkap

- Inspeksi Kualitas Miturut Fasilitas Sate-of-the-art

- Persetujuan Peraturan Rohs/REACH

- Perjanjian Non-Disclosure NDA

- Kebijakan Mineral Non-Konflik

- Review Manajemen Lingkungan Reguler

- Pemenuhan Tanggung Jawab Sosial

Tungsten Carbide Ready to Press Powder (RTP)

produk sing gegandhengan

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu